Already for some time a new beacon of light has made its appearance in the media, that promises to revolutionize the growing of food and to ease the problem of insufficient and moreover dwindling agriculturally productive land by cultivating urban landscapes. This bearer of hopes is called Vertical Farming and claims to be able to produce food in the protecting folds of specially constructed multistory buildings. A realization of this concept would not only be promising to put an end to hunger in this world, but also to simplify the process of growing food and to reduce the application of biozides and other chemistry. If the latter really applies may be debatable for the time being. But there are legitimate doubts that the realization of this idea is really that simple. But it can certainly be done.

Already for some time a new beacon of light has made its appearance in the media, that promises to revolutionize the growing of food and to ease the problem of insufficient and moreover dwindling agriculturally productive land by cultivating urban landscapes. This bearer of hopes is called Vertical Farming and claims to be able to produce food in the protecting folds of specially constructed multistory buildings. A realization of this concept would not only be promising to put an end to hunger in this world, but also to simplify the process of growing food and to reduce the application of biozides and other chemistry. If the latter really applies may be debatable for the time being. But there are legitimate doubts that the realization of this idea is really that simple. But it can certainly be done.

Far greater doubts concern the question of the profitability of Vertical Farming, especially so if one takes a closer look at the factor of light. For every other thing, that is water and nutrients, cycles can be established, and with sufficient insulation even heat might be produced more or less self-sufficiently. But the factor light has to continually be produced anew, and the energy needed for this can hardly be generated within the system.

So far there do not seem to be any available calculations in the internet that give a positive impression on the feasibility of Vertical Farming, especially with regard to the factor of lighting. One may even get the impression that the problem of lighting is extremely underestimated.

One can think of two possible reasons for this. One of the reasons may be based on the assumption that the earth is a closed and self-sufficient system and that everything nature needs to live and thrive is produced or regenerated via a variety of circulations, and that it should be possible to reproduce this system on a smaller scale. But it seems to be overlooked that the function of the light of the sun is not primarily to allow us to see but to keep the terrestrial system going – and it pours a lot of energy into this system.

The other reason might be found in the fact that the human eye is quite adapt in adjusting to extremely small amounts of light and therefore the in reality tremendous difference between the usual office lighting and direct sunlight seems negligible.

But appearances are deceptive, and it is this question of lighting that could be the downfall to this nice concept of Vertical Farming.

To create at first a somewhat unfavorable scenario, one can try to simulate the open air conditions within the isolated system of a Vertical Farming building with easily available everyday technology. Here are two numbers for a first impression about the dimensions that have to be tackled: on a sunny day one can measure a luminous intensity of about 100.000 lux. Well illuminated office rooms show a luminosity of 500 lux at most, that is 0,5 % thereof. The luminaire Skylife 1480 is designed to give the impression of islands of sunlight within office and presentation rooms and illuminates with 12 fullspectrum fluorescent 54 W tubes an area of 2 m² with a composition that closely resembles sunlight. According to the manufacturer it produces a brightness of 2.500 lux at a distance of 1 m.

With these details we have a first starting point to make a projection regarding the light production. It should be possible to fit 20 fluorescent tubes into the same area and thus produce 4000 lux with an energy requirement of about 500 W/m² . Let us assume that the performance of the fluorescent tubes could be augmented in any way we like or need then we would have – linearity provided – an energy requirement of 12,5 kW/ m² in order to produce 100.000 lux. The usual fullspectrum tubes cost about 20,- EUR each (all measures are of German/European origin). The cost of these super fluorescent tubes can hardly be estimated, but with a 25-fold performance 50 EUR each certainly are not too much. With 20 tubes per 2 m² we have 500 EUR/ m² cost of materials for a life of about 12.000 hours.

Officially wheat (as an example staple food) has a a vegetation period of at least 90 days. Working with 15 hours a day this results in 1350 hours. This in turn results in 56 EUR/m² costs for the tubes and 3375 EUR costs for power at 0,2 EUR/kWh – together 3431 EUR. Usually we can have a harvest of 0,8 kg wheat from 1 m². As we have optimized conditions regarding the care of the plants one might be generous and assume a harvest of 2 kg. This would mean, that the production of 1 kg wheat would cost about 1700 EUR without including proportionate costs for the building, maintenance, means of production and working hours.

Admittedly, this calculation is rather unfavorable, but is it really possible to reduce this number to 1 EUR, that is at least 99,94 % less? To find this out we must try to explore the currently most favorable possibilities.

In biological research sometimes environmental chambers are used. These are isolated rooms in which all climate factors including lighting can be controlled, independent of the real weather. With the aid of these chambers it was researched which kind of light the plants actually need for photosynthesis and therefore for their growth. Responsible for photosynthesis is chlorophyll which exists in two forms: one form uses red light, the other blue light. All the other components of the sunlight’s spectrum exert at most a marginal influence on the plants. Both these colors of light make up an estimated 30 % of the sunlight’s energy. Therefore to produce light selectively that satisfies the demands of the plants, only about 30 % of the energy required for the spectrum of sunlight is needed.

As the scientists tended towards reasonable, economical and effective possibilities for lighting, special lamps have been developed for environmental chambers. They are produced in a multitude of color compositions and performances. The newest developments are arrays of powerful red and blue LEDs. But now at this stage it becomes rather difficult to comprehend the connections between daylight intensity (in lux), the share of photosynthetically productive light and the units of measurement for this kind of lamps (μmol/m² sek)

So we have to rely on one of the producers who has given a light performance of 1400 μmol/m² sec. at a distance of 0,35 m for one of these lamps. It requires a power of 300 W/ m² and costs about 850 EUR. Duration: 50.000 hours. If we apply these numbers to our example of wheat production then we have 23 EUR cost of materials and 405 EUR for power – at 2 kg wheat/ m² this means 214 EUR/kg.

To come down to as much as 1 EUR/kg we would still have to lower the costs by 99,5 %. At the moment this seems pretty much impossible. For this the cost of the luminaires would have to decrease by 99,9 %. The degree of effectiveness of LEDs is about 15 %. If we would succeed to reach an effectiveness of 100 %, that means to transform all the energy into light (which is not possible physically), then we would still have power costs of 30 EUR/kg.

The nature of the difficulty can also be visualized with another image: If we have a 10-story-building for Vertical Farming then for the plants in this building we need the sunlight that illuminates an area that is 10-fold the size of the building’s base. If we wanted to generate the required energy with photovoltaic systems (projected effectiveness somewhen in the future by maybe 30%) and use a light source with 30 % effectiveness as well, then we would need an area 100 times the size of the building’s base.

Or one considers how much energy is needed to artificially illuminate the comparatively small area of an hectare: with 300 W/m² a performance of 3 megawatt is needed. With a reasonably modern atomic power plant of 300 MW performance about 100 ha can be provided with power and so about 1000 people can be nourished, because of the improved performance of controlled growing conditions maybe even 4000 people. To nourish the population of New York City in this way 2000 such power plants would be needed.

Though the numbers are basically the same one can maybe form an image of the dimensions easier, if one looks at the power question from another angle. If we want to produce 1 kg wheat, to stay with this example, and put aside for the moment the costs of the lighting hardware, then we may only consume energy of the value of 1 EUR for the whole growing period (though strictly speaking the price of wheat is only 20 cent). With optimistic 2 kg/m² this means an acceptable consumption of 10 kWh/m² in 90 days or, in other words: the illumination hardware for 1 m² may only have a max. power requirement of 7,4 W, but has to produce as much light as the sun.

But agriculture is the area of food production with the least turnover per m². Truck farming, especially in greenhouses has a significantly higher turnover and is in its nature much more akin to Vertical Farming. A well doing company with the added benefits of optimized lighting all the year round might well make a turnover of about 100 EUR/m². With 15 hours a day this means 2 cent/h or a max. power of 100 W for the illumination of 1 m². At first glance this seems to be almost realizable, great technological achievements provided. This number might be situated on this side or beyond the border of physically attainable things, which meams that it might not be realizable at all. And the rise of energy prices might aggravate the situation, as their rise might be steeper than the rise of food prices.

Up to now we have disregarded the usual aspects belonging to real business management, because the numbers were so preposterous that their inclusion had been futile. But when we rename Vertical Farming into Vertical Horticulture we reach areas that are a tad bit nearer to reality, so that there is now a certain necessity to take these aspects into account. A great share of the costs belongs to the hardware, that is to the lighting installations. With the aforementioned reasonable technology of the environmental chambers these amount per year to 90 EUR/m². To this have to be added the costs for manpower, possibly heating, other means of production, plot and building. So one can safely assume that already the necessary costs to facilitate Vertical Horticulture are much higher than the realizable turnover and the expected costs of power for the illumination amount at least to the turnover. This means, that food produced in this way would cost a multiple of conventionally produced food.

These numbers show very clearly, that the concept of Vertical Farming, as brilliant and enticing as it may seem, due to physical and economical restrictions cannot be realized in a convincing way, at least not here on earth. But if we use this concept on the moon this is quite a different matter. Due to the astronomically high costs for the transport of food the production in sublunar chambers would definitely be worthwhile, with the added boon, that because of the moon’s lack of atmosphere solar energy is available in abundance and comparatively cheap.

For us here on earth, where we have to struggle with the ever present shortage of energy – or rather a too abundant use of energy – this means that we have to reconsider the means that are available to us – that is the earth’s surface. This is continuously built up (preferably fertile areas) and mistreated so heavily that its fertility and the content of humus are steadily decreasing (the latter, by the way, seems to contribute in no small manner to the increase in atmospheric CO2) and the nourishing of 7 billion people becomes always more difficult. It should still be feasible, if we think globally and are seriously determined to solve this problem, to feed the world’s population with the present possibilities without really serious problems. Prerequisite for this is a global will to cooperation, the end of war and greed for power and money, the revaluation of agricultural activities and a sustainable care for the soil in order to preserve and subsequently increase the soil’s fertility. And maybe also the thesis should be questioned, that the tendency towards the always bigger in agriculture and horticulture and the continuous reduction of the genetic pool of the useful plants through the cultivation of increasingly less varieties is able to uphold on the long run the efficient provision of food.

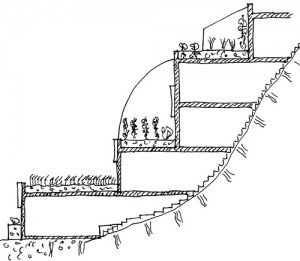

Nevertheless the idea of at least Vertical Horticulture need not be totally dismissed, although it will almost certainly not be realized in its original form of multistory buildings. With every new house we build, we seal part of the earth and loose fertile soil in exchange to living space. A realizable Vertical Horticulture can only come about by lifting cultivatable space above the living space, whether with or without greenhouse protection.  Examples for this are living pyramids whose steps are covered by greenhouses or cascading earth houses,

Examples for this are living pyramids whose steps are covered by greenhouses or cascading earth houses,

but also conventional buildings, whose sunny sides are enlarged by balconies of at maximum 3 m width and glass fronts, so as to use the sun energy for the cultivation of edible plants (see my book on Eco-Habitats – sorry, for the moment only in German). This procedure creates synergies. Thick soil on the rooftops provides effective insulation which is further enhanced by greenhouses, a certain amount of food can be produced where it is needed and less cultivatable soil gets lost forever. And should it be necessary, supportive lighting could be used during the winter months – profitability provided.